Technology

- Home

- TREATMENT & CONSULTATION

- Motor suction

- Planmeca Proline XC Digital X-ray

- Hextio Viruskiller

- Image plate scanner

- Motor suction

- Philip Zoom Whitening

- เครื่องดมแก๊ส Nitrous Oxide

- Extra Oral Suction

- 3shape scanner (TRIOS 3)

- Airflow

- Asahi Intraoral x-ray

- Air Purifier

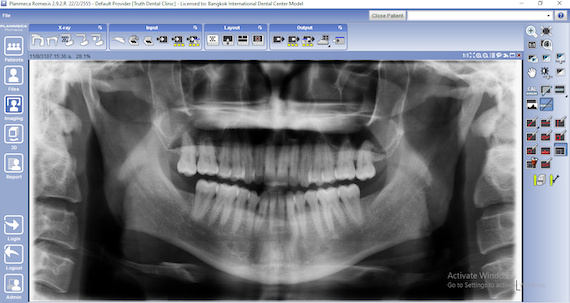

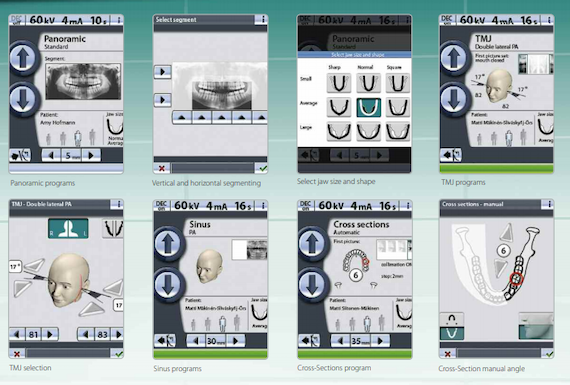

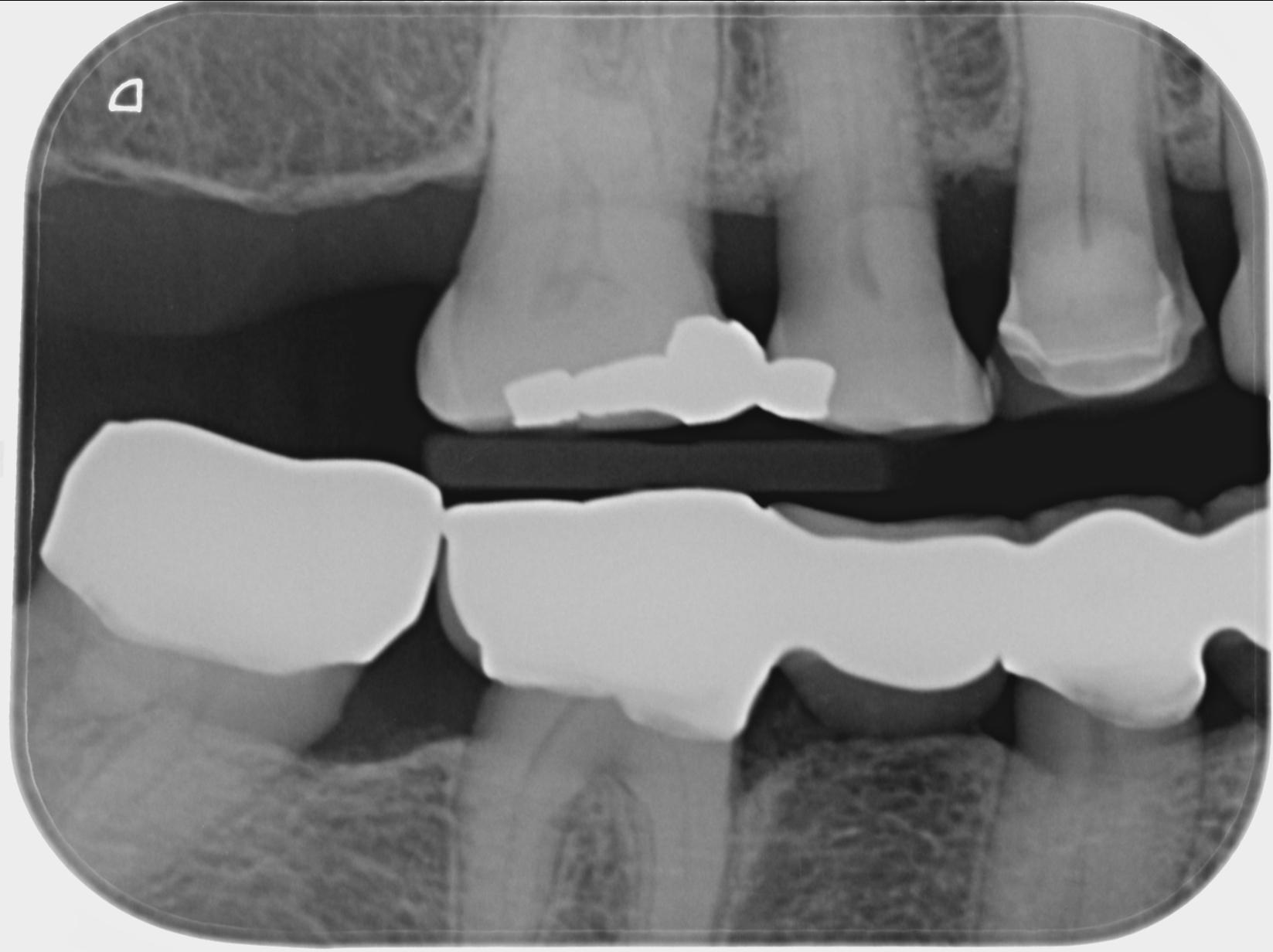

Planmeca Proline XC Digital X-ray

- Direct digital imaging saves time: Images are seen on the computer screen within seconds after the exposure without waiting for the processing of film in order to make a proper diagnosis.

- Proline’s CCD Direct Digital Technology: The digital sensor technology of the ProOne eliminates chemical processing of films, as well as the need for chemical developers, chemical disposal, and dark room. Digital imaging puts an end to the retakes.

- Easy to operate: The Proline X-ray unit provides absolute ease of use with cutting edge digital imaging technology. Simply select the desired image program, patient type, jaw shape and size, and position the patient. The unit’s graphical user interface ensures that all types of radiographic examinations are highly rapid and effortless to perform.

- Accessible by all patients: The PLANMECA Proline easily handles any patient, from children and adults to those who are bedridden or wheelchair bound.

- Side entry: The PLANMECA Proline’s side entry feature allows easy access for all patients; the exposure can be performed on a standing or a seated patient. If necessary, the patient can even remain seated in a wheelchair or lie in a hospital bed with upright lifted backrest.

- Open view patient positioning: The Proline X-ray does not require mirrors to position the patient. Instead, the patient has an open and comfortable view. (This is especially useful when, for example, the patient is a small child who needs reassurance that a parent is nearby.)

- Quick and easy patient positioning: The Proline X-ray’s side entry and open patient positioning features minimize radiograph errors caused by incorrect patient positioning. Patient positioning is made quick, precise, and easy, as the user may monitor the patient freely from the front and side.

- Triple laser beam alignment: Patient positioning is assisted by a triple laser beam system which accurately indicates the correct anatomical positioning points. The midsagittal plane positioning beam shows the correct sideways alignment of the patient’s head. The Frankfort horizontal plane positioning beam allows the correct head tilt. The focal layer positioning beam helps position the patient accurately inside the focal layer for a sharp and clear image.

- Digital imaging allows easy archiving and efficient record-keeping practices: A digital image requires much less storage space, it’s easier to access, and can be found in much less time than a film image.

PLANMECA ProOne provides a variety of imaging programs for different radiographic needs. In addition to the the standard panoramic programs, the following specific imaging programs represent a few of the programs included within the optional Professional Program Package:

- Improved Interproximal Program

- Improved Orthogonal (Perio) Program

- Bitewing Program

Note: The panoramic Bitewing Program can be added as a separate program. ProOne also allows you to select the right exposure parameters, minimizing the radiation dose for all types of patients and diagnostic purposes. ProOne’s advanced imaging geometry efficiently eliminates shadows and ghost images caused by objects outside the image layer, which significantly increases the diagnostic value of the radiograph.*

ProOne Digital Panoramic X-ray Programs

All 5 Basic Programs come standard with the unit. The Professional Program Package is optional and contains over 12 advanced panoramic programs including the Bitewing Program. The optional Bitewing. Example Romexis Software, Romexis Software Tools, TWAIN Driver, DICOM Compliant, Complete Digital Imaging.

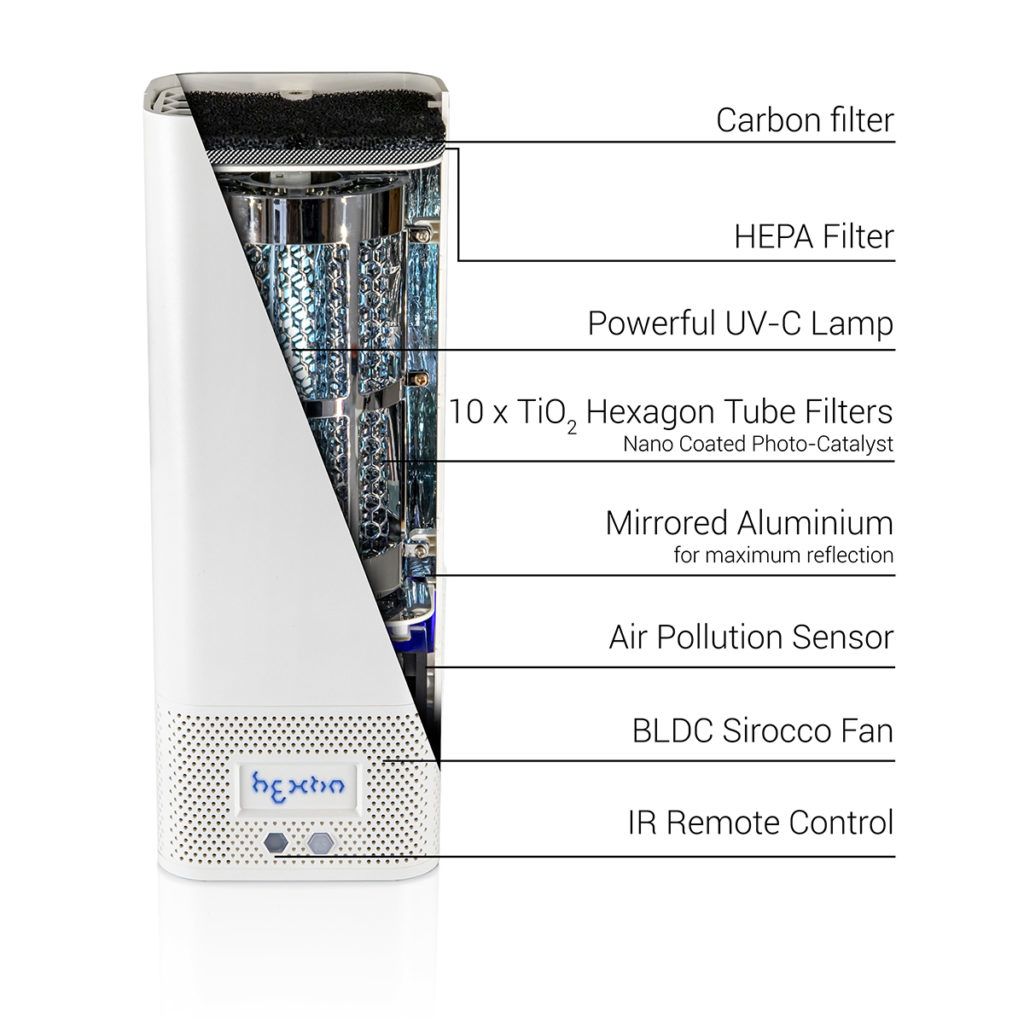

Hextio Viruskiller

Hextio is personal air protection. Ideal for an individual with the unit situated on a desk, counter, bedside table, in a private vehicle, or on the go.

Hextio is the perfect air decontamination unit for personal use, thanks to its powerful fan and advanced photocatalytic oxidation technology developed for VIRUSKILLER™.

Hextio neutralizes pathogens in an individual’s breathing space. The only desktop air purifier with VIRUSKILLER™ technology, Hextio is your personal clean air companion at work or at home.

Suitable for desks, counters, bedside tables, and even on the go, this portable unit can be powered by a 12V power bank. The compact and lightweight Hextio is the perfect portable clean air companion.

What you'll be protected from

- Viruses

- Bacteria

- Pollen

- Formaldehyde

- Mold

- Nitrogen Dioxide

- Hazardous Vapors

- VOCs

- Allergens

- Exhaust Fumes

- Spores

- Particulate Matter

Hextio has been proven and tested to:

- Deactivate viruses and bacteria with unequalled efficiency

- Eliminate high levels of pollution from indoor air

- Effectively remove noxious gases and larger particles such as dust, dander, and other allergens

Hextio’s airflow hood can be directed towards an individual’s breathing space, providing clean, safe air, regardless of their surroundings. With no installation required, Hextio is plug-and-play indoor air safety for people on the move.

Process for complete air decontamination

As air passes through Hextio, it goes through a two-stage process of purification and decontamination. Like many high-end air purifiers, Hextio features a premium HEPA filter to trap ultrafine particles and allergens as air moves through the unit.

The activated carbon filter traps dust, pollen, smoke, and VOCs — this is where most air purifiers end and Hextio begins.

Featuring a miniaturized Reactor Chamber inherited from Radic8’s VIRUSKILLER™ enabled devices, Hextio uses photocatalytic oxidation to safely and efficiently decontaminate airborne viruses and biological pathogens that may pass through conventional filters.

Hextio is a complete filtration, neutralization, and decontamination device designed for your desktop.

The Radic8 technology has been recognized with international standard certifications. There are numerous patents associated with the VIRUSKILLER™ Reactor Chamber. The Radic8 technology has also been certified Ozone Free.

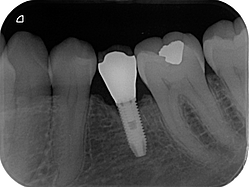

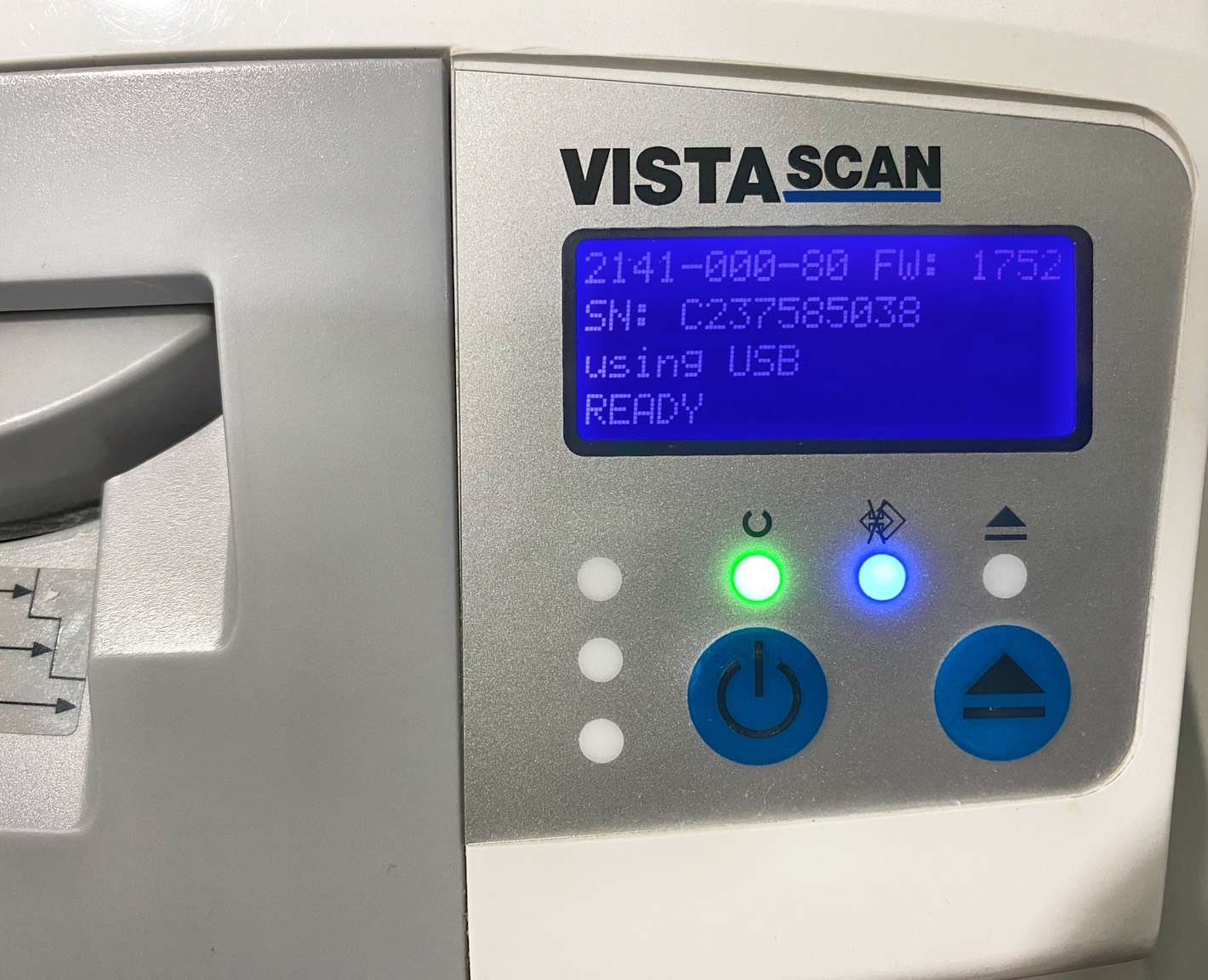

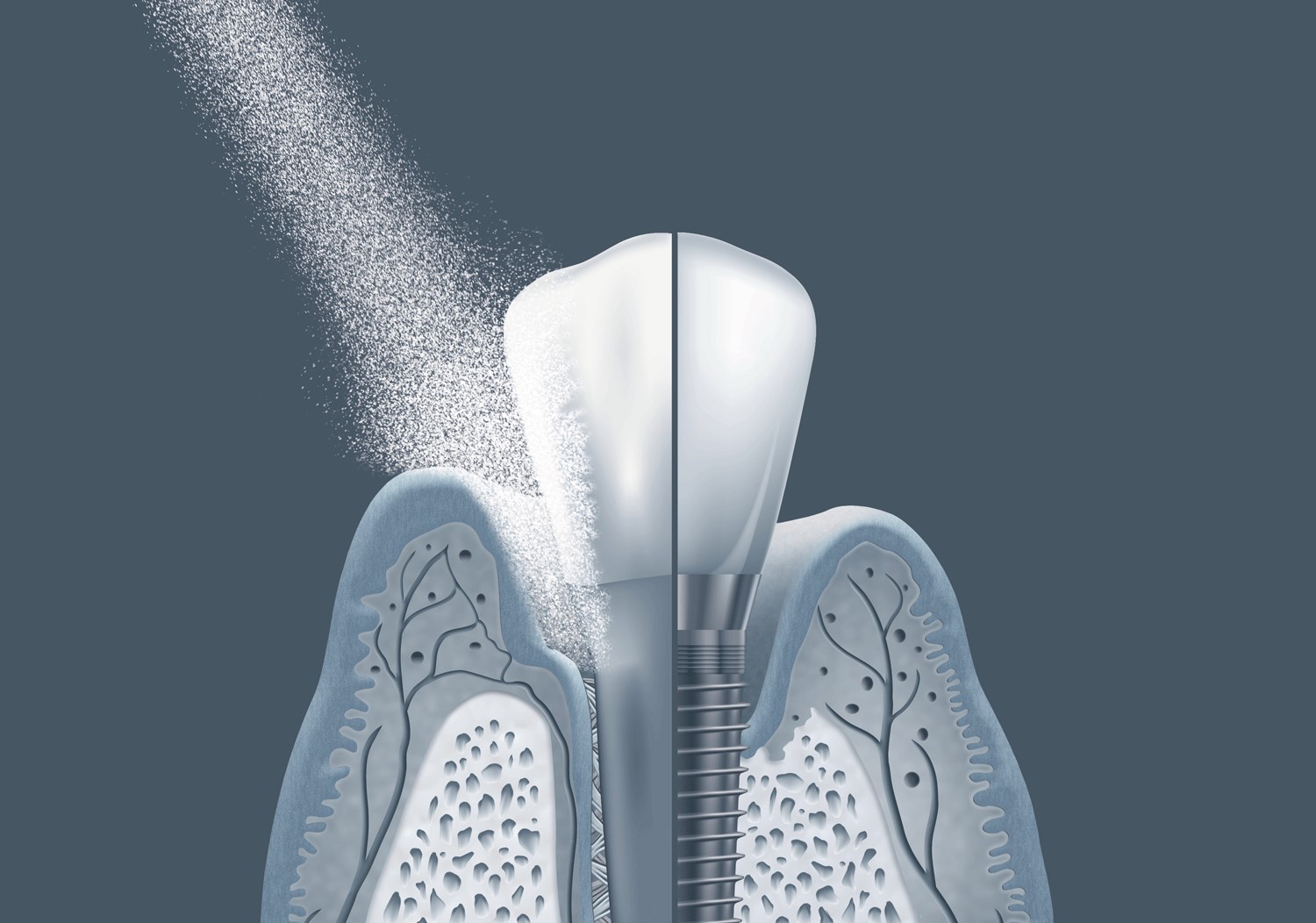

Image plate scanner

VistaScan Mini Plus – "red dot design award winner 2011"

Since the introduction of conventional X-ray film development in dentistry, Dürr Dental has been at the cutting edge of diagnostics in the surgery. Digital X-ray with Dürr Dental offers dentists images with high resolution to meet all diagnostic demands. More than 50 years' experience in the development of X-ray technology leads time and again to practice-oriented and innovative solutions.

The VistaScan Mini image plate scanner makes image plate diagnostics even faster for dentists. The compact device is particularly easy to use and requires a minimum of space – so that it can be installed in the treatment room.

The advantage:

X-ray and scanning directly at the chairside with full flexibility in the image formats. The re-usable VistaScan image plates are read out in top quality within seconds. There's never been a better time to change over to plates.

Features

- Compact without compromise: The grey scale graduation of the image plate with VistaScan Mini permits a presentation commensurate with the quality of the plate. With the proven engineering and outstanding image quality characteristic of Dürr Dental image plate scanners worldwide. Made in Germany.

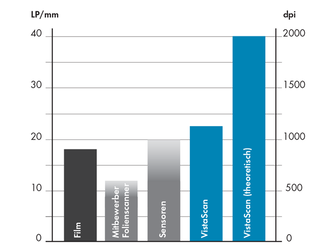

- No compromises on image quality: VistaScan Mini can reliably resolve caries D1 lesions and endoinstruments down to ISO 06. With 22 LP/mm, 16-bit (65.536) grey scales

- No compromises on simplicity: Particularly easy handling: Read out, delete and make ready for the next use in one step. Rapid image availability from 6 seconds on in the direct vicinity of the patient.

- No compromises on integration: VistaScan Mini can be operated with DBSWIN or other software packages via plug-ins or Twain drivers.It can be easily integrated into the surgery infrastructure via the USB or network interface.

- No compromises on flexibility: All intraoral image plates – from size 0 to 4 – can be used with VistaScan Mini. In addition, 100% active surface area is available. Simple handling – as with an analog film.

- No compromises on configuration: The display shows the most important patient data and information on the scanning process at a glance. Including energy-saving stand-by function.

- Highest image quality, perfect presentation: With a detail recognition of 22 LP/mm, VistaScan image plates have a higher resolution than the X-ray film and exceed that of any competitors. The Photon Collecting System (PCS) from Dürr Dental is already ahead of current image plate developments.

- Faster and more reliable diagnostics: Changeover from X-ray film to "digital" image plate? There's nothing easier than that. the X-ray exposure procedure remains the same as before. However, the diagnostic reliability is increased thanks to optimum detail recognition and sophisticated software support. With the VistaScan Mini you can benefit from all the advantages of the Dürr Dental image plate technology in its most compact form. The thin, flexible image plates are more pleasant for the patient and are particularly durable thanks to their special coating.

Motor suction

Durr V 300 S

The V-suction unit is suitable for use in dry air suction systems. The advantage of this system is that the suction units can be installed in any suitable room, regardless of the actual connection layout and routeing of the lines. The necessary air flow and vacuum are generated by a rapidly rotating impeller. An auxiliary air nozzle on the turbine housing protects the suction units against overheating. When an appropriate vacuum for the machine is applied, approx. 300 l/min of air is sucked in through the suction cannula.

On the vacuum side the V-suction unit is equipped with a condensation separator that collects any condensation arising within the pipe system and transports it away to the outside.

The VS suction units are used in wet suction systems. The suction units can be installed on the same floor as the treatment units or on the floor underneath. The necessary air flow and vacuum are generated by a rapidly rotating impeller. An auxiliary air nozzle on the turbine housing protects the suction units against overheating. When an appropriate vacuum for the machine is applied, approx. 300 l/min of air is sucked in through the suction cannula. The impeller, the separation turbine and the waste water pump are driven by the motor. The mixture of liquids, solid particles and air drawn in passes through the inlet connection and into the suction unit. The coarse filter holds back the solid particles.

Inside the separation unit, the aspirated fluids and solid particles pass through a two-stage separation system and are separated from the suction air. This separation system consists of a cyclone separator and a separation turbine. The suction process runs continuously.

The aspirated mixture flows into the cyclonic separator, where it is set into a spiral motion. In this first stage, the resulting centrifugal forces force the fluid constituents and any remaining solid particles against the outside wall of the separation chamber of the cyclone separator. This initially only effects a "coarse separation" of the fluid. In the subsequent second stage, the separation turbine effects "fine separation" of the remaining liquid from the air flow that has carried it to this point.

The waste water pump transports the liquid from the centrifuge together with the fine solid particles through the waste water connection into the central waste water network. A diaphragm valve is located in the waste water connection to prevent fluid from the drain being sucked back in.

This device has been subjected to conformity acceptance testing in accordance with the current relevant European Union guidelines. This equipment conforms to all relevant requirements.

Philip Zoom Whitening

Philips Zoom WhiteSpeed, the No.1 patient-requested professional whitening brand1, is clinically proven to whiten teeth up to eight shades in 45 minutes2. With clinically superior results and efficacy versus other professional whitening alternatives, WhiteSpeed is one of the fastest ways to create brighter, healthier smiles that patients will want to show off. WhiteSpeed's light-accelerated technology speeds up the whitening process, delivering dramatic results your patients will love in just one office visit.

Benefits

- Variable settings: Customizable intensity settings help ensure each patient receives a comfortable, positive whitening experience catered to them. In fact, 99%3 of patients surveyed experienced little to no sensitivity during the Philips Zoom WhiteSpeed treatment.

- Advanced blue LED technology: Philips blue LED light-accelerated technology provides 50,000 hours of use, reducing operating costs and downtime and decreasing energy consumption by 40%. The results and efficacy, showing 55% better results with our 25% HP light-activated gel versus 40% HP gel.

- Everything you need in our kits: Each Zoom WhiteSpeed Procedure Kit contains everything you need to perform a Zoom procedure in just a few steps. Each kit also contains an exclusive Patient Post Care & Maintenance Kit. Patient kits include a syringe of Relief® ACP Oral Care Gel to help manage sensitivity.

- Ensure little to no sensitivity: While 99%3 of patients surveyed experienced little to no sensitivity with Philips Zoom WhiteSpeed, tooth sensitivity is a potential risk with all whitening procedures. Place a light coating of Relief® ACP on the lingual surfaces of teeth being whitening before treatment. Following the procedure, use Relief ACP in trays for 10 to 30 minutes to reduce sensitivity.

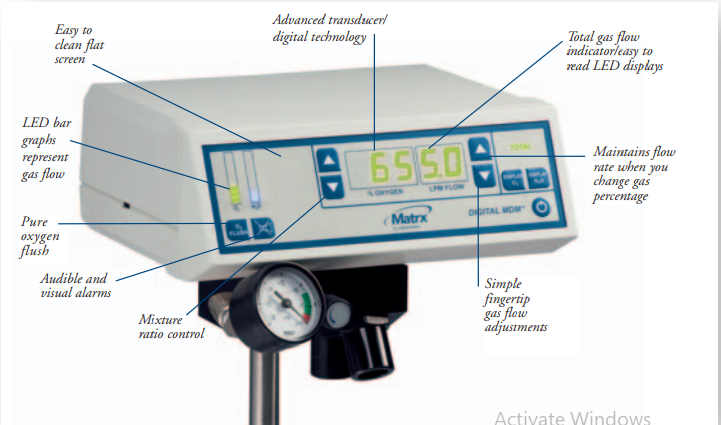

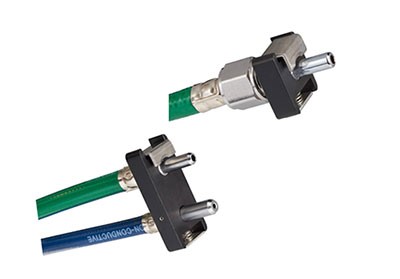

เครื่องดมแก๊ส Nitrous Oxide

Nitrous oxide and oxygen (N2O/O2) provide a safe, simple and fast-acting alternative to oral medications for minimal sedation. During the procedure, patients experience reduction in pain and anxiety due to the analgesic and anxiolytic properties of N2O. After the procedure is completed, the effects on the patient wear off within minutes.

Nitrous oxide has been used for 100+ years, proved to be both effective and safe, few side effects, Ease of administration, Physician, nurse, or patient self-administered.

Matrx nitrous oxide breathing circuits and nasal hoods deliver a safe and predictable experience for both adult and pediatric patients. The design of the Matrx breathing circuit is streamlined and lightweight for patient comfort as well as simplicity of use. Adjustable to any manufacturers breathing circuit.

Nitrous Oxide Advantage

- Nitrous oxide takes effect and is out of the patient's system within a few minutes

- Complete procedures more efficiently

- Reduced recovery time and staffing for patient monitoring

- Patients return to normal activities quickly

- Improved patient care

- Offer more ways to efficiently relax and provide comfort for your patients

- Safety record

- Rapid onset and short duration of effect

- Attract patients by offering safe, effective, pain management

- Save time - rapid onset and recovery

- Able to titrate drug to allow precise and incremental control of delivery with no waste

- Relaxed patients remain fully conscious and able to respond to directions

- Easy to administer and control

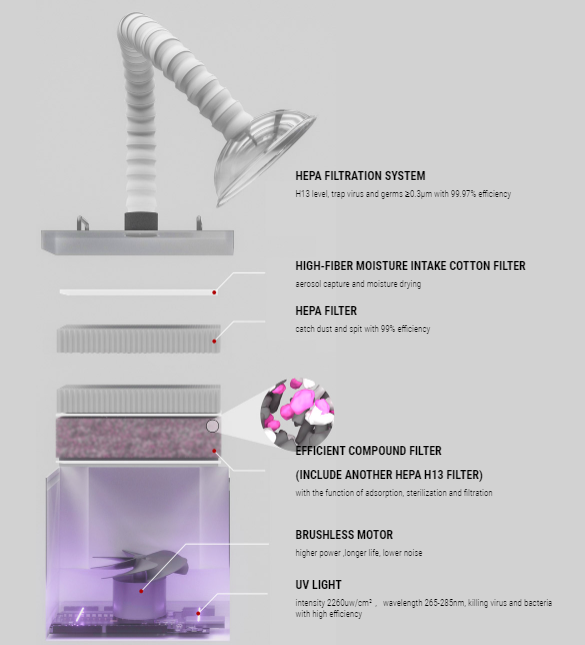

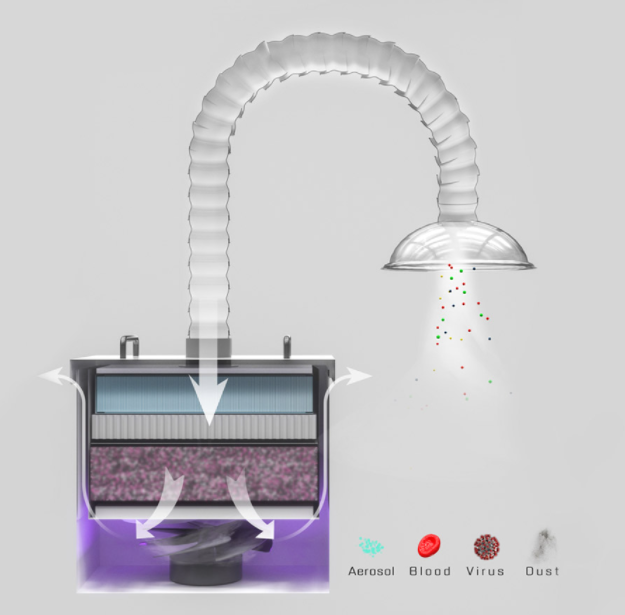

Extra Oral Suction

VacStation is an extraoral aerosol vacuum device to prevent blood,virus,dust and other substance from spreading in dental treatment like high-speed drilling, dental laser and electrosurge procedures, etc

VacStation Extra-oral Dental Suction System has been developed by Eighteeth to reduce the risk associated with airborne particulates and pathogens present in an aerosol spray that is an inherent part of dental care. The aerosol emerging from the mouth of the patient consists of splashes of the spray mist rebound and droplets containing cooling water, saliva, blood, microorganisms, bacterias and viruses. This mixture presents a high risk of infection.

VacStation reduces that risk and purifies the air using a multi-level filtration system (HEPA, High-fiber cotton filter, Activated carbon+KMnO4+Ceramsite filter+2nd HEPA 13), and UV C light. It traps viruses and germs ≥0.3 μm with over 99.97% efficiency, including mercury vapor. An independent evidence-based study has found that using the VacStation in conjunction with a high volume suction, would justify having 10-15min.fallow time.

SARS-CoV-2: characterisation and mitigation of risks associated with aerosol generating procedures in dental practices - British Dental Journal (2021)

Studies have shown that nasal swabs from patients with symptomatic or asymptomatic Covid-19 exhibit higher viral concentrations than those in throat swabs. High volume aspirator would not protect against viruses exhaled by patients through the nose. Extraoral vacuum aspirators (EOVAs), like VacStation, deal with both aerosol droplets and viruses exhaled through the patient’s nose.

Even a modified household vacuum is “highly effective in preventing air contamination by dental procedures”

Did you know:

- Over 600 different types of bacteria can be detected in the human oral cavity (Source: Genome Research (2009), DOI: 10.1101/gr.084616.108)

- 1 ml saliva contains about 10 million bacteria (Source: Genome Research (2009), DOI: 10.1101/gr.084616.108)

- During a 15-minute treatment without protective measures, approx. 0.014–0.12 µl of saliva is inhaled via the aerosol (Source: Bennet et al. British Dental Journal, Vol. 189 No. 12 (2000))

- Deposition of a co

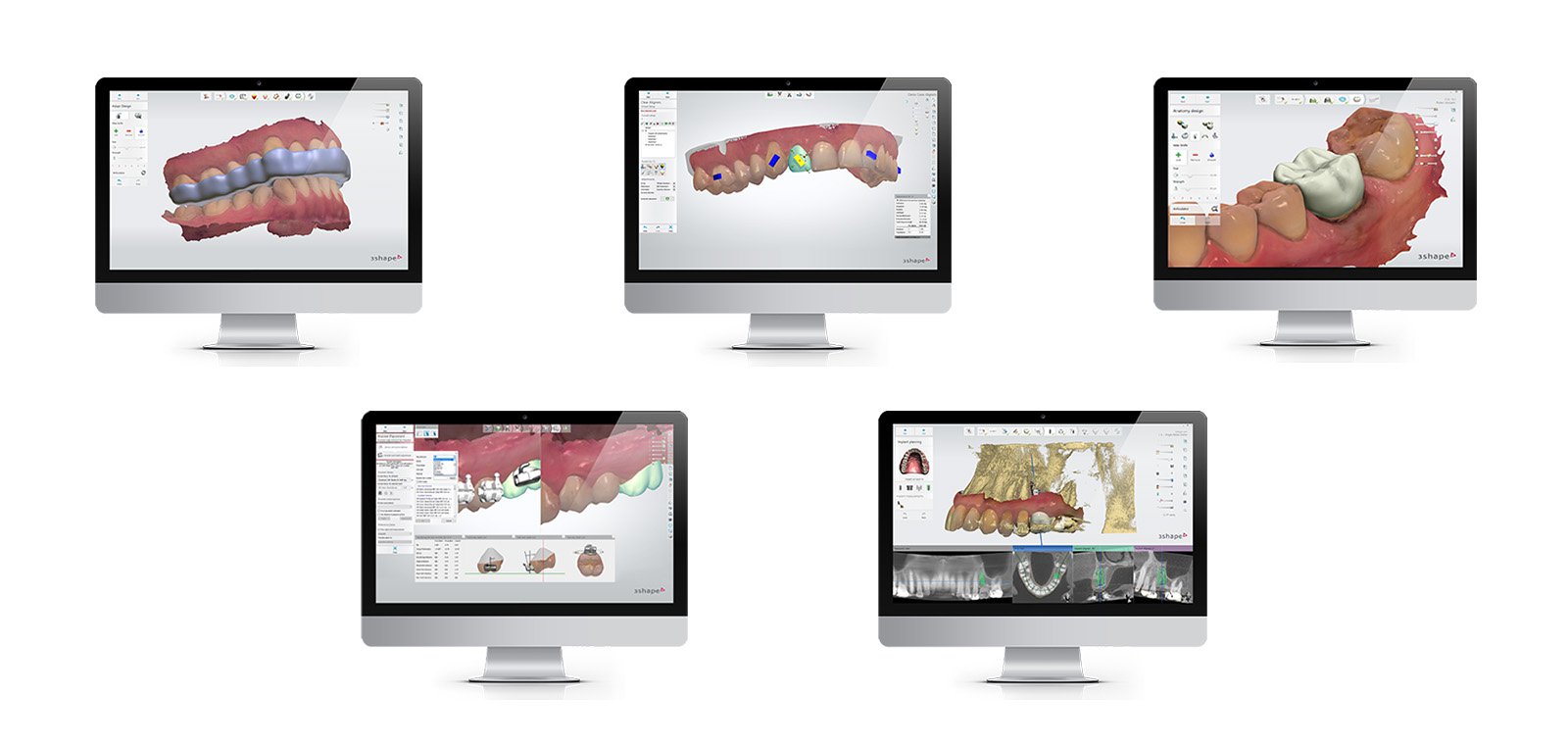

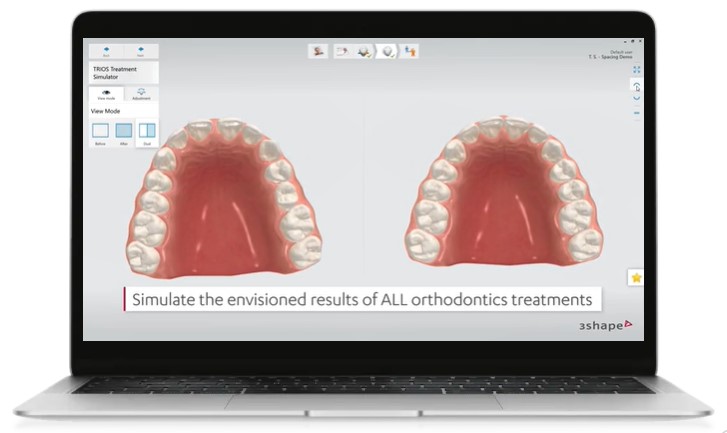

3shape scanner (TRIOS 3)

The intraoral scanner built to boost patient engagement. Preview restorative and orthodontic treatment results. Explain the treatment plans more easily.

Features & Benefits

1. Superior technology: Our scanner use AI to learn from real teeth for long-lasting, natural-looking treatment outcomes. We can even capture and send precise occlusion and excursive jaw motion to the lab for a perfect fit. And digital scanner dental impressions are more accurate than conventional impressions.

2. Software for engagement and treatment: Combine TRIOS 3 Wireless with our engagement apps as visual tools to help you personalize patient experiences and ensure all your concerns are addressed. Together, we create a perfect opportunity to show the patients their unique dentition and share specific information about the health of your teeth and gum.

3. Wireless innovation: Scan unrestricted by wires and quickly move your scanner between different operatories. We ensure optimal comfort and easier scanning for the patients.

4. Future smiles: TRIOS can do smile design to design beautiful new smile in just minutes, based on a photo of your patient’s face. Share the photorealistic results with the patient.

Airflow Acteon Satelec P5 Newtron Scaler

Satelec® piezoelectric ultrasonic generator : Suprasson® P5 Newtron. Combining the benefits of powerful Newtron® technology in the state-of-the-art control module and the ergonomics of the patented Satelec Color Coding System, the P5 Newtron® provides the best performance and the widest choice of ultrasonic instruments available in the marketplace today. The Newtron technology enables real-time adjustment of the tips’ single plane oscillation amplitude (Cruise Control™) which means a smooth, constant and powerful vibration during treatment.

AIR-N-GO EASY

- Adaptable handpiece for either SUPRA and SUB-gingival treatments

- 4 nozzles for perfect removal of pathogenic bacteria

- Complete range of powders to provide customized solutions for all clinical needs

- Gentle and efficient treatments for better patient comfort

AIR-N-GO Classic Powders have been specially designed and studied to produce effective treatment that is gentle on all treated surfaces.

- Sodium Bicarbonate-based (≈ 76μm). 5 fresh flavours based on 100% natural aromas or essential oils : Neutral, Cola, Raspberry, Peppermint and Lemon.

- Remove stains and bacterial plaque, even in areas that are difficult to access such as pits and fissures.

- Better patient comfort: gentle and efficient with limited bleeding during treatment.

- Combining water, air and powder, AIR-N-GO Easy results from the most advanced fluid dynamics modelling techniques, provide continuous, accurate and controlled spray whatever the clinical context.

Asahi Intraoral x-ray

Features

- High resolution image quality and reduction of radiation dosage are realized by X-ray Tube Head with 0.4mm focal spot and proprietary inverter control method.

- 0.8mm Tube head focal spot is adopted. We are pursuing high resolution image quality.

- X-ray generator with light 4.5kg body enables smooth positioning to the exposure portion.

- Lineups of abundant kinds of equipment enables installation to X-ray room of various conditions.

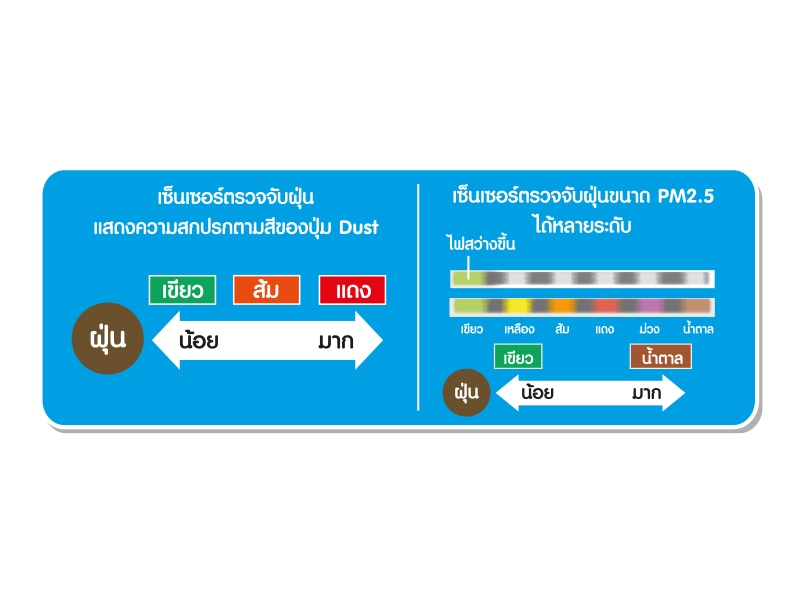

Air Purifier

Daikin's air purifier cleans the air with Streamer discharging technology to restrain. viruses, bacteria, allergens and odors. It is as well equipped with Electrostatic HEPA filter that is capable of collecting dust. Cover over 31 sq.m room.

- Streamer technology, purify the air which taken into the purifier

- Restrain H1N1 - H5N1 viruses, bacteria, germs, and odors

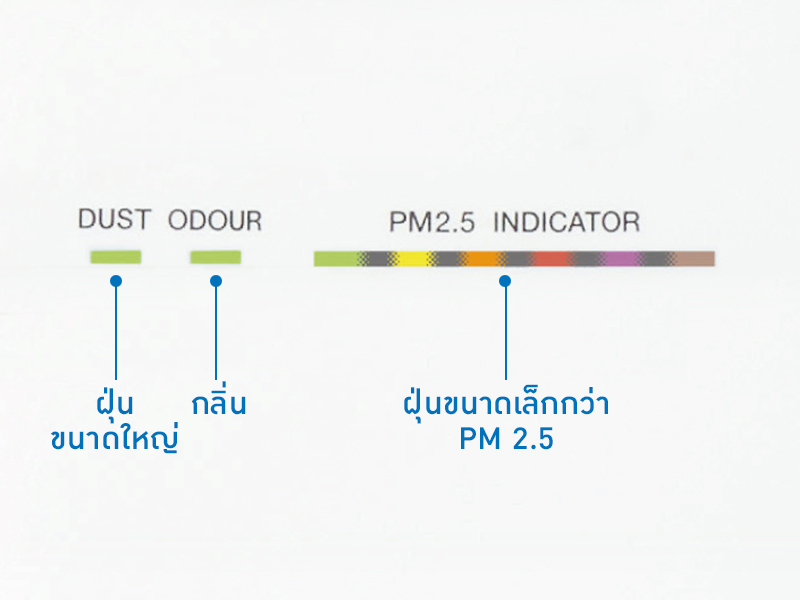

- Maximum of 6-level dust measurement up to PM2.5

- Lifetime odor filter

Features

- Streamer Technology: The streamer discharges the plasma electron with high-speed that could decompose viruses, bacteria, fungus, hazardous chemical substances and allergens. Its decomposing power toward those certain pollution is as equal as the 100,000 C heat.

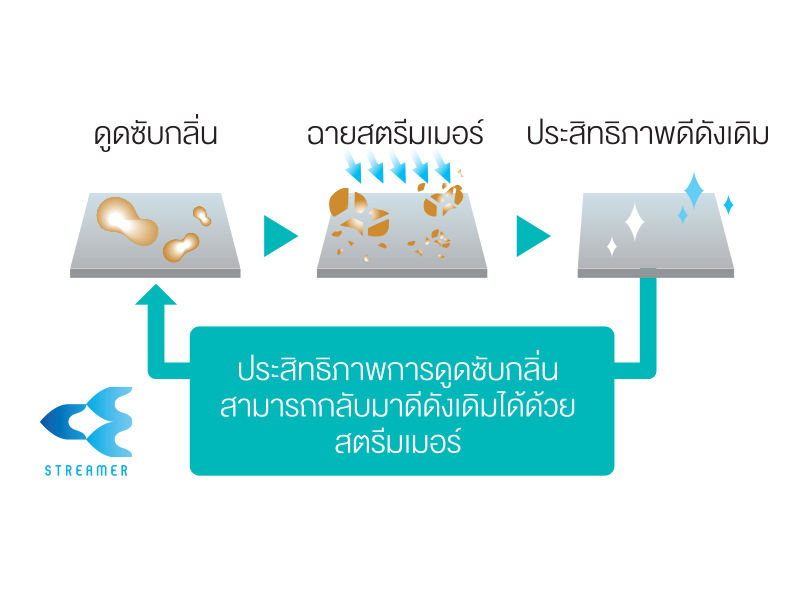

- Deodorizing Filter: Carbon-type deodorizing filter can remove the unpleasant odors by using the Streamer technology to eliminate odors and dirt.

- Slim Design: The tower-like design, can be placed at all corners of the room, takes space only 27 x 27 cm

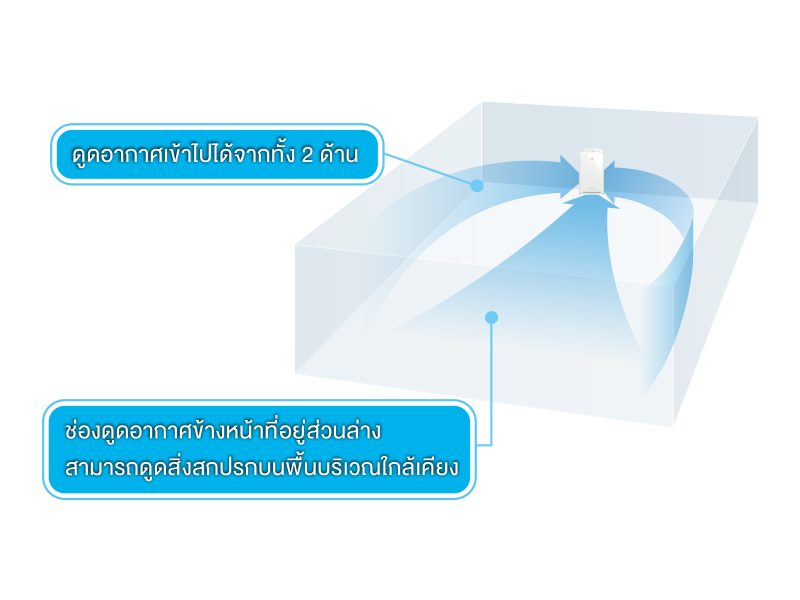

- 3-way air inlet and can be placed next to the wall: 3-way air inlet (front-left-right) and 1 way air outlet at top of the purifier. So, it can be placed near the wall.

- Minimum quiet operation at 19 decibels: The large-size air outlet reduces the operation sound. Fan's position is placed at the bottom part while filter acts as the sound-absorbing sheet that make the minimum quiet operation sound at only 19 decibels.

- 3 Dirt-Detection sensors: Intensive particles detection sensor can filter large dust and small particle which is smaller than PM 2.5. In Auto Mode, the purifier can deodorize and purify the air to eliminate the unpleasant air.

- 6-level of dust detector: Maximum of PM2.5 dust detector with 6-level of censoring.